The seismic support is the mechanical and electrical engineering facilities such as water supply and drainage, fire fighting, heating, ventilation, air conditioning, gas, heat, electricity and communication of buildings after seismic reinforcement Bai. When encountering the earthquake with seismic fortification intensity in this area, it can reduce the earthquake damage and reduce and prevent the occurrence of secondary disasters as much as possible, So as to reduce casualties and property losses.

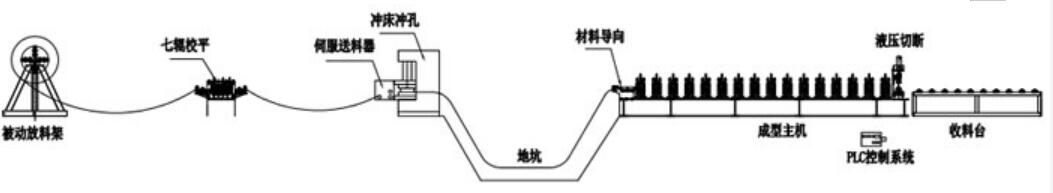

Machine Detail:

Specification:

| Forming machine frame | 22-25 forming stations, plus multiple auxiliary forming rolls |

| thickness | 1.5~2.75mm |

| Forming speed | 0~8M/MIN |

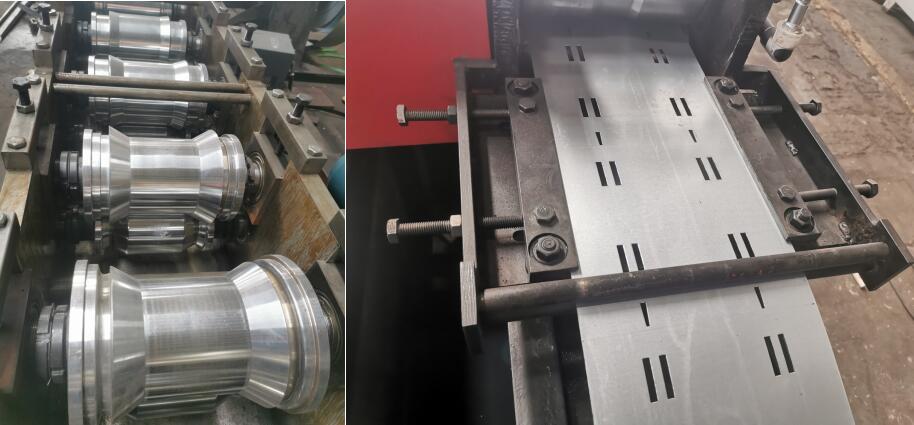

| Roll material | Cr12 |

| Motor power | 15KW motor with cycloidal pinwheel reducer |

| Side plate structure | Adopt 40mm wallboard side plate |

| Spindle material | CR40 modulation treatment, spindle diameter: 70mm |

| Cut off mode | Hydraulic cut-off universal knife |

| Cutting tool material | Cr12Mov |

| Power of hydraulic station | 7.5KW |

| Transmission mode | 1.5 inch single row chain |

| Installed capacity | 30KW |

| Length of production line | 24M |

| Weight | 12T |

safety protection:

The whole line is equipped with emergency stop button, which is easy to deal with emergencies and ensure the safety of equipment and operators. The transmission parts such as chains and gears that are easy to cause damage to workers are covered with protective covers to ensure the safety of workers.

Control system:

PLC control system: Panasonic brand

Frequency converter: Yaskawa Yaskawa brand

Encoder: Omron OMRON