Electrical control system of Positive Pressure Air Supply outlet Production Line:

PLC: Panasonic of fpx-c30t

True color touch screen: Taiwan Winon

Detection encoder: Japan internal secret control encoder

Servo drive system: Viktor (or invetion) servo drive system

Low voltage electrical appliances: circuit breakers and contactors are domestic famous brand "Chint" electrical appliances, and relays are"Omron" or "Schneider".

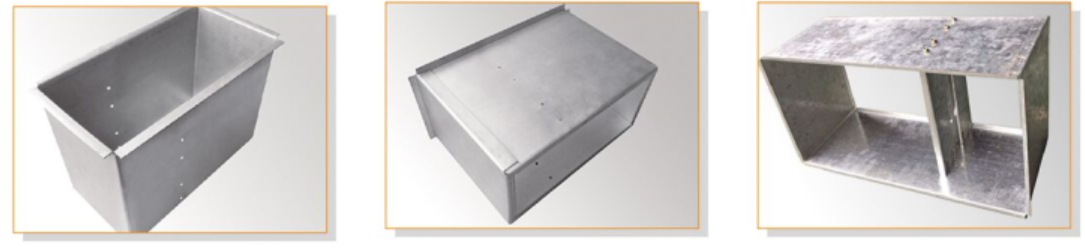

Finished Products:

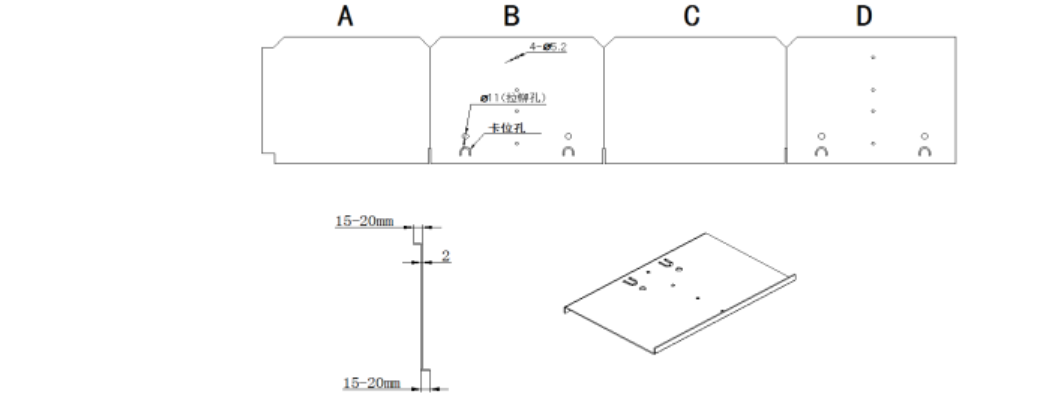

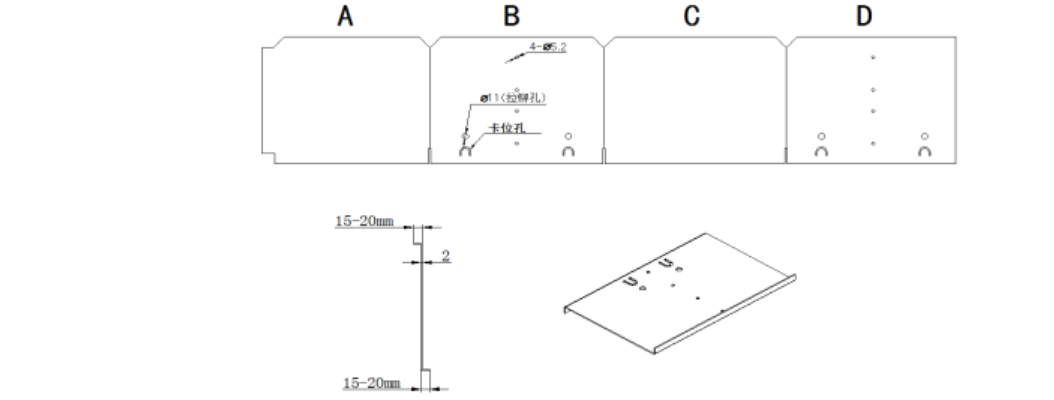

Product drawing:

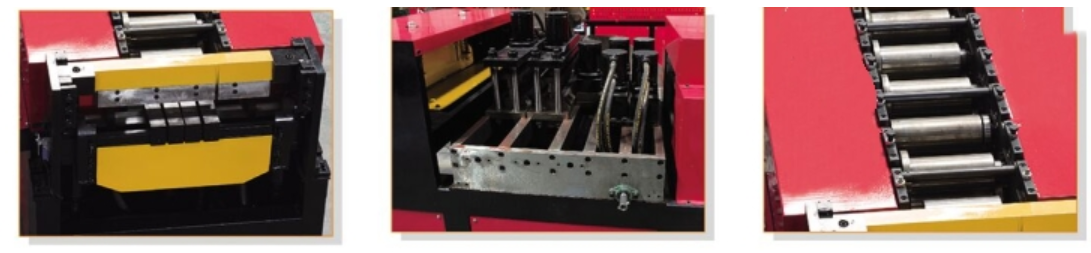

Detail of Machine:

Description of function:

●Double servo driving,full automation operation

●Frame width: 200(240)mm

●Frame type:L shape/口 shape/single chip

●Speed:350 pieces/8 hours

●Continuous order production mode

Basic Part:

1.One powerless decoiler

2.One suit of leveling equipment

3.Separately two suits of big nothing molding and small molding

4.One suit of impact machine constitutive hole molding

5.One suit of punching baffler fixed hole molding

6.One suit of hydraulic shearer

7.One set of feeding platform

8.One set of frame molding

9.one suit of hydraulic bender

10.One suit of digital controlling system

11.Two suits of hydraulic pressure system