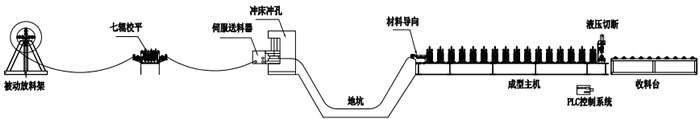

Some parameters of production equipment for cold bending of cable tray: Equipment process flow: feeding (manual)-plate leveling-hydraulic punching and cutting by encoder-cold bending forming-finished product supporting-unloading (manual). Performance characteristics:

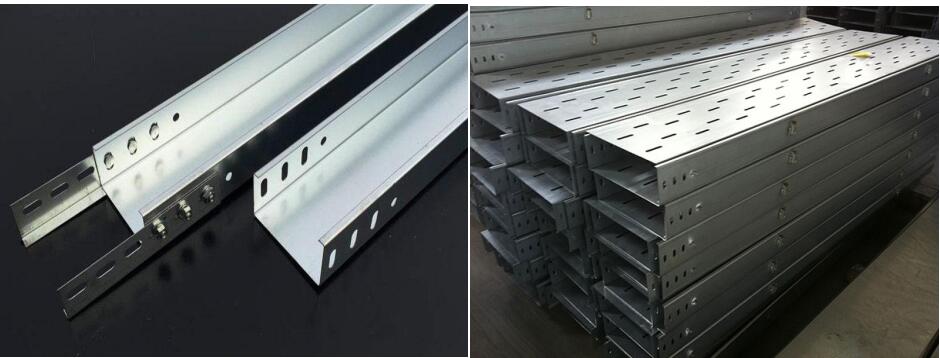

1. The layout of cold bending forming equipment for cable tray is scientific and reasonable, and it has a wide range of adaptability to the hardness and hardness of galvanized strip steel, which is not easy to damage the zinc layer in the rolling process;

2. Equipment. With servo feeding, hydraulic or punch punching is generally used, and strip steel can be punched continuously to produce various types of cable bridges, such as disc type, groove type and ladder type. The rolling machine with double cantilever structure can realize arbitrary adjustment within the width range, save the time of replacing the plate shape and improve the production efficiency;

3. PLC control of the whole line, color touch screen input, frequency conversion speed regulation;

4. Operators need 1-2 people.

Specificaiton:

| Forming machine frame | 18 forming stations, plus multiple auxiliary forming rolls |

| thickness | 0.5-2.5mm |

| Forming speed | 4~8M/MIN |

| Roll material | Cr12 |

| Motor power | 15KW motor with cycloidal pinwheel reducer |

| Side plate structure | Adopt 40mm wallboard side plate |

| Spindle material | CR40 modulation treatment, spindle diameter: 70mm |

| Cut off mode | Hydraulic cut-off universal knife |

| Cutting tool material | Cr12Mov |

| Power of hydraulic station | 5.5KW |

| Transmission mode | 1.5 inch single row chain |

| Installed capacity | 50KW |

| Length of production line | 30M |

| Weight | 15T |

safety protection:

The whole line is equipped with emergency stop button, which is easy to deal with emergencies and ensure the safety of equipment and operators. The transmission parts such as chains and gears that are easy to cause damage to workers are covered with protective covers to ensure the safety of workers.

Control system:

PLC control system: Panasonic brand

Frequency converter: Yaskawa Yaskawa brand

Encoder: Omron OMRON

Work Flow: